Smart Window Patching Machine – Precision & Efficiency Redefined

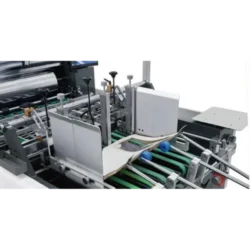

Revolutionize your packaging production with the FKT-BMW1050L Window Patching Machine. This large-format, high-speed automated asset is engineered for superior precision and reliability, essential for competitive scaling in the modern packaging market.

| Model name |

FKT-BMW1050L |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Window Patching Machine

Delivering target speeds of 7,500 sheets per hour and exceptional stability, this Window Patching Machine functions as a high-performance packaging machine and represents a strategic investment to secure high-value contracts in pharmaceutical, food, and premium retail packaging.

Product Specification

| S/L | Source Feature/Finding | Customer Requirement |

| 01 | Max.paper size: W1030×L720mm Min.paper size: W150×L150mm Max.Film size: W500×L350mm Min.Film size: W50×L50mm Film thickness: 0.08-0.3mm heating up to 0.4 mm Paper thickness Corrugated board: ≤5mm Cardboard: 200-2000g/m² Positioning Accurate ±0. 5 mm Max Machine speed: Max 7500sheets/hour Power supply: AC380V, 3 phase, 50Hz Power: 17.5kW(heating increases by 6kW) Air supply: 0.8MPa,>0.3m³/min Overall dimension (L x W x H): 8000×1920×1800mm Net Weight:3500kg | Window Patching Machine V Shape & Plain Shape both Option required |

Advantage & Features

The BMW Series automatic corner-cutting and wire-pressing window patching machine integrates standard flat patching with film window patching functions, including V-cutting and creasing. It can perform double creasing, double cutting, circular cornering, round hole punching, and eco-loop marking on PVC, PET, and PP films with a thickness range of 0.08–0.3 mm.

Featuring an innovative transverse film-cutting system, the machine operates at high speed with low noise. Its unique gluing mechanism can be disengaged to prevent adhesive from getting on the belt when there’s no paper feed. An optional double-sided tape system can be added for online use.

With digital control, all parameters can be fine-tuned during operation. The machine is also equipped with multi-sensor detection at each station, providing real-time monitoring and automatic speed-reduction alarms in case of abnormalities, ensuring a perfect operation. Designed with continuous improvement and user-friendly principles, it offers exceptional efficiency, precision, and stability while being easy to operate.

Applications

The FKT-BMW1050L Window Patching Machine is engineered to meet the quality, compliance, and aesthetic standards of fast-growing industries. Its precision and versatility make it ideal for:

- Pharmaceuticals: Fully compliant with WHO CGMP standards. High-precision automated patching prevents contamination and misalignment, ensuring product integrity and regulatory safety.

- Export-Oriented and Food Packaging: Ideal for export-grade packaging like frozen seafood. Supports diverse films (OPP, PET, PVC) to ensure hygiene, durability, and extended shelf life under international quality standards.

- FMCG & Premium Retail: Enhances visual appeal for products like cosmetics, tissues, gifts, and handicrafts. Handles complex barrier protection for sensitive items, delivering both functionality and premium presentation.

Product Comparison Table with Similar Products

| Specification | FKT-BMW1050L (Target Class) | Wenzhou Hengtong (ZKT-750B) | KOTEN (TC-1020 Dual Lane) |

| Max Speed (Pcs/h) | 7500sheets/hour | 4,000−10,00017 | 1,200,018 |

| Max Paper Width | 1050 mm | 750 mm17 | Approx. 1020 mm |

| Paper Caliper Range | 200-2000g/m² Cardboard | 250−1000 g/m2 + Corrugated$^{17}$ | 200−500 g/m2 + Corrugated$^{18}$ |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The FKT-BMW1050L Window Patching Machine comes with a service warranty that covers technical malfunctions and performance issues related to the machine’s core window patching and feeding operations. Some components—such as glue nozzles, belts, rollers, and other consumables—naturally wear out over time and are therefore not covered under the warranty. If any covered part experiences failure during the warranty period, our technicians will provide the necessary repair or replacement service, but customers will be required to purchase any spare parts needed. Please note that all shipping costs for sending or receiving parts or equipment are the responsibility of the customer.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Frequently Asked Questions

Q: What is the primary ROI driver for this Window Patching Machine?

A: Beyond speed and labor savings, precision is key—defects under 1% save costly materials.

Q: Is this machine suitable for food-grade packaging?

A: Yes. It features 304 stainless steel rollers, fast cleaning, and supports high-barrier films.

Q: Is local service and support available for this Window Patching Machine?

A: Yes, Prominent Tec in Bangladesh offers installation, training, service, and spare parts

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.