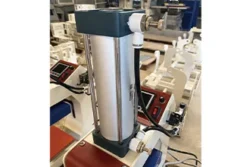

Single Station Pneumatic Mark Heat Press Machine for Printing

Elevate your printing business in Bangladesh with the PT-J2 pneumatic single station transfer machine. Engineered for efficient and precise heat transfer, this industrial-grade pneumatic heat press is the ultimate solution. As a leading driver mark heat press machine, it is designed for applying logos, labels, and intricate designs onto a variety of materials.

| Model name |

PT-J2 |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Single Station Pneumatic Mark Heat Press Machine

The Single Station Pneumatic Mark Heat Press Machine is a core element of professional finishing solutions, featuring a pneumatic operating system that ensures consistent, high-pressure application for flawless and professional heat transfer results. Designed for the fast-paced garment and promotional industries in Bangladesh, this durable Pneumatic Mark Heat Press Machine combines robust industrial construction with user-friendly controls. The PT-J2 Single Station Pneumatic Mark Heat Press Machine is an ideal solution for businesses looking to improve production quality, consistency, and output efficiency.

Product Specification

| Model | Printing Area | Maximum Temperature | Voltage | Power | Gross Weight | Package Size |

| PT-J2 | 150*150mm | 260℃ | 220V/110V | 400W | 18kg | 380*310*700mm |

Advantage & Features

The machine adopts a pneumatic operation design with a quality driver and motor. A key component is the pneumatic cylinder system that transforms low pressure from an air compressor into a strong compression force. Its up-and-down pneumatic mechanism, combined with a single-station worktable, makes the process faster and easier, with less chance for error compared to manual operation.

Some of its key attributes include:

- Heating Platen: The high-quality platen is equipped with technology for fast heating, ensuring you can get to work quickly.

- Electronic Control: An electronic digital panel with intuitive software makes setting temperature and time a convenient process.

- Customization Options: OEM services are available to personalize the machine to your specific needs.

Applications

-

Garment Factories: The Pneumatic Mark Heat Press Machine works perfectly as a single-station label heat press for applying brand labels, care instructions, and size tags on finished garments and cut fabric pieces.

-

T-Shirt Printing Businesses: Ideal for small logos and chest prints, the Pneumatic Mark Heat Press Machine is a reliable tool for custom designs on T-shirts, jerseys, and teamwear.

-

Personalized Items: This Pneumatic Mark Heat Press Machine is well suited for producing custom-branded apparel, gifts, and personalized products, including portrait images, landscape designs, and unique patterns.

-

Promotional Product Suppliers: The Pneumatic Mark Heat Press Machine easily transfers logos and branding onto tote bags, mouse pads, and other promotional items, making it highly effective for advertising and corporate gifting.

-

Sublimation Printing: Suitable for sublimation on small polyester-coated items and fabrics, delivering clean, vibrant, and durable results.

Product Comparison Table with Similar Products

| Feature | PT-J2 Pneumatic Mark Heat Press | Manual 15×15 Heat Press | Standard Mug Press Machine |

| Operation | Pneumatic (Automated) | Manual (Hand-operated) | Manual |

| Pressure System | Air Compressor (Consistent) | Manual (Variable by operator) | Manual Clamp (Fixed) |

| Ideal For | High-volume label/logo pressing | Small-scale, varied projects | Mugs and cylindrical items only |

| Consistency | Very High | Operator Dependent | High (for its specific purpose) |

| Operator Fatigue | Low | High | Moderate |

| Typical Price Range in BD | Moderate – High | Low | Low – Moderate |

| Best Suited For | Professional Garment Finishers | Startups, Hobbyists | Specialized Drinkware Businesses |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Pneumatic Mark Heat Press Machine comes with a service warranty that covers any functional issues related to the machine’s pneumatic system, digital control panel, and heating plate operation. Some items—like the Teflon sheet, silicone pad, and air hose connectors—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Frequently Asked Questions

How do I start using the PT-J2 Single Station Pneumatic Mark Heat Press Machine?

Plug in the machine, set temperature and time, pre-press the garment, position the design, press the dual safety buttons, then peel as instructed.

How do I set up the Pneumatic Mark Heat Press Machine after unboxing?

Place it on a stable table, connect the air compressor and power supply, and run a heat test before production.

How do I adjust temperature and time on the Single Station Pneumatic Mark Heat Press Machine?

Set the required temperature and time using the digital control panel.

How can I press a logo on a sleeve using the Single Station Pneumatic Mark Heat Press Machine?

Set temperature and time, align the sleeve and logo, press, then peel after the beep.

How do I adjust pressure on the Single Station Pneumatic Mark Heat Press Machine?

Use the pressure adjustment knob near the air inlet to increase or decrease air pressure.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.