Ordinary Tunnel Drying Machine with Conveyor Belt for Reliable Garment & Screen Printing Curing

Bangladesh’s vibrant textile and garment sector, coupled with a growing demand for high-quality screen printing, necessitates robust and efficient drying solutions.

| Model name |

PT-K2 |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Ordinary Tunnel Drying Machine

The PT-K2 Ordinary Tunnel Drying Machine, part of the reliable PT-K series, is a key component of professional finishing solutions, designed to meet the rigorous demands of modern production environments. This Ordinary Tunnel Drying Machine delivers stable performance, continuous operation, and consistent drying quality, making it a dependable solution for businesses across Bangladesh seeking efficiency and production stability.

Product Specification

| Model | Belt Length (L*W) | Length of Healing Area | Belt Speed | Max.Temperature | Machine Dimensions (mm) |

| PT-K2 | 8000*1000mm | 6000mm | 2-16m/min | 2400 C | 8000*1260*1350 |

Advantage & Features

- Features a conveyor belt for continuous operation, significantly boosting productivity.

- Electronic temperature control ensures precise and stable heat distribution.

- Built-in air circulation system maintains consistent drying quality for clothes.

- Conveyor speed is adjustable with stepless drive control for flexible operation.

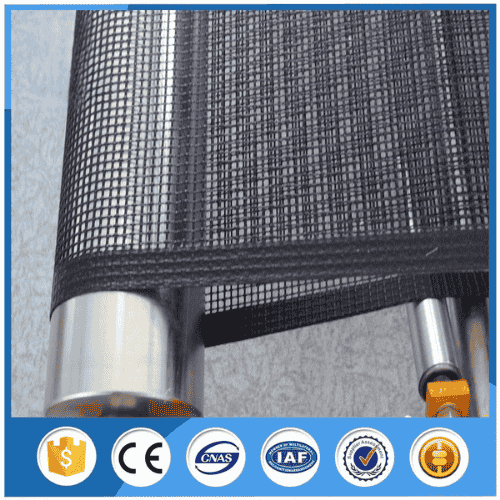

- The interior is made of galvanized steel, enhancing infrared reflection, speeding up cooling, and delivering excellent curing results.

Applications

The PT-K2 Ordinary Tunnel Drying Machine is widely used in industries that require efficient, consistent drying and curing. In Bangladesh, common applications include:

-

Screen Printing Industry: The Ordinary Tunnel Drying Machine is essential for curing plastisol, water-based, and UV inks on garments and fabrics, ensuring durability and consistent print quality.

-

Textile & Garment Manufacturing: Used for fabric pre-drying and post-treatment processes where steady, controlled heat is required.

-

Packaging Industry: Suitable for drying and curing inks on printed packaging materials using conveyor-based drying.

-

General Industrial Drying: Ideal for flat materials that require even heat distribution and controlled drying through a tunnel conveyor system.

This Ordinary Tunnel Drying Machine enhances both production speed and output quality across these sectors.

Product Comparison Table with Similar Products

| Feature / Dryer Type | PT-K2 Series (Ordinary Tunnel Dryer) | Advanced IR Tunnel Dryer | Forced Air Tunnel Dryer | Hybrid Tunnel Dryer (IR + Forced Air) |

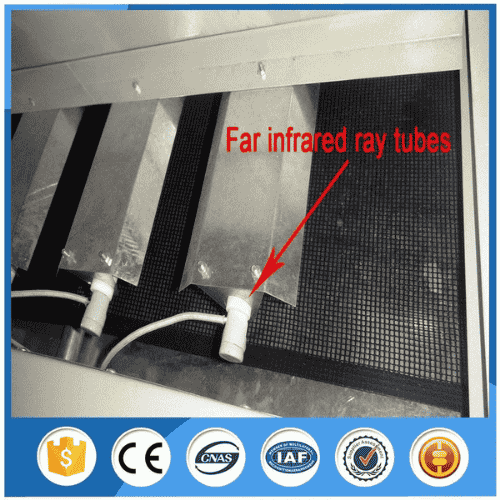

| Heating Method | Far Infrared (IR) + Hot Air Circulation | Primarily Far Infrared (IR) | Primarily Hot Air (Convection) | IR & Forced Air (Combined) |

| Ink Suitability | Plastisol, Water-based, UV (versatile) | Plastisol (excellent), Water-based | Water-based (excellent), Plastisol | All ink types (optimal versatility) |

| Curing Speed | Good, efficient | Fast for plastisol | Fast for water-based | Very Fast (optimized for all) |

| Energy Efficiency | Good (Hot Air Recirculation) | Good (Direct IR heating) | Variable (depends on design) | Excellent (synergistic heating) |

| Temperature Control | Electronic, precise | Very precise | Precise | Highly precise |

| Footprint | Standard industrial tunnel dryer size | Can be more compact for high output IR | Standard to large | Standard to large |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The PT-K2 Ordinary Tunnel Drying Machine comes with a service warranty that covers its core electrical components, motorized conveyor system, and basic temperature control unit. Some items—like conveyor belts, heating tubes, and insulation materials—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Frequently Asked Questions

Q1: Is the PT-K2 Ordinary Tunnel Drying Machine suitable for both plastisol and water-based inks?

A1: Yes, it cures both plastisol and water-based inks effectively with proper temperature and belt speed adjustment as per ink guidelines.

Q2: How does the PT-K2 Ordinary Tunnel Drying Machine series contribute to energy saving in the tunnel dryer machine?

A2: It uses hot air circulation and far-infrared pipes to cut energy waste and boost heat efficiency, reducing electricity use.

Q3: What are the power requirements for this Ordinary Tunnel Drying Machine in Bangladesh?

A3: It requires a 380V/50Hz three-phase power supply with consumption ranging from 21 kW to 26.5 kW. Voltage stabilizers are recommended in areas with frequent power fluctuations.

Q4: What maintenance does an Ordinary Tunnel Drying Machine require?

A4: Routine maintenance includes cleaning, checking electrical connections, inspecting heating elements, lubricating moving parts, ensuring proper ventilation, and scheduling periodic professional servicing.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.