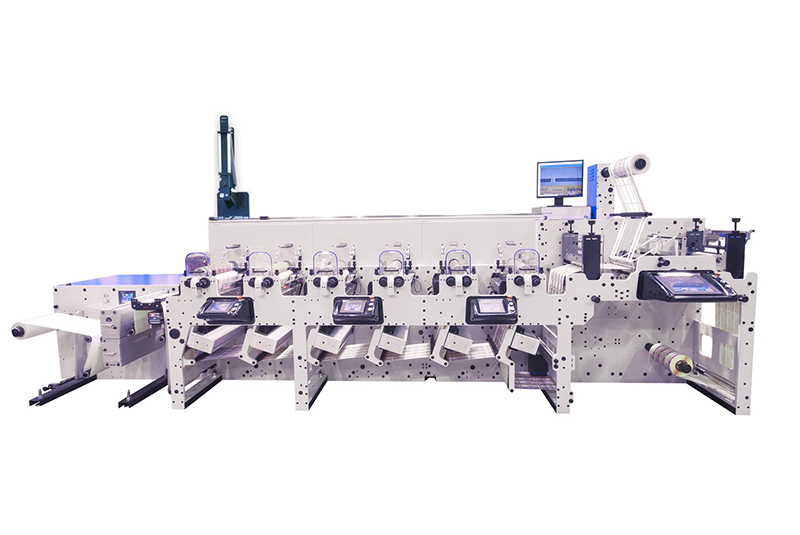

Focus Proflex SE Printing System Machine – Cost-Effective, High-Quality Label Printing machine

The Proflex SE is a state-of-the-art, servo-driven modular flexographic printing press, part of the latest proflex range of modular equipment designed for converters in Bangladesh demanding precision, speed, and versatility.

| Model name |

PT |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

Proflex SE

Engineered by Focus Label Machinery UK, this high-performance Proflex SE machine is the definitive solution for producing premium labels and flexible packaging, seamlessly supporting modern flexo printing requirements. This SE version is available with servo drive technology and enables your business to capture high-value markets with unparalleled print quality, attention to detail, and consistency throughout every run. Elevate your production capabilities with the powerful Proflex SE.

Product Specification

| PROFLEX ‘Se ‘250 | PROFLEX ‘Se’330 | |

| Number of Colours | 10 Max | 10 Max |

| Digital Ink jet Integration (requires UV drier) | Mono & Colour Option | Mono & Colour Option |

| Max Web Width | 260mm(12.25”) | 336mm(13.25”) |

| Max Print Width | 254mm(10”) | 330mm(13”) |

| Max/Min Print Length | 188-510mm(7-20”) | 188-510mm(7-20”) |

| Gearing (Spur or Helical) | 3.175 (1/8C.P) | 3.175 (1/8C.P) |

| Infra red Drying (Independently adjustable) | Std (2 Kw/Col ) | Std (2 Kw/Col ) |

| LED UV | Optional | Optional |

| U.V Drying | Optional | Optional |

| Chill Rolls | Optional | Optional |

| Slitting | Yes | Yes |

| Rotary Die Cutting | Yes | Yes |

| Rotary Sheeting | Yes | Yes |

| Max Unwind Reel Diameter | 1000mm(40”) | 1000mm(40”) |

| Max Rewind Reel Diameter | 850mm(22”) | 850mm(22”) |

| Other Options | Turn bar, Delam/Relam, Lamination, Digital Ink Jet, Cold foil, Hot Foil, Rotary Silk Screen, Sheet Stacker, Corona Treater, Web Cleaner, Auto Register, Fan Folder, Ticket Streamer, U.V Drying, Chill Rolls. | |

Advantage & Features

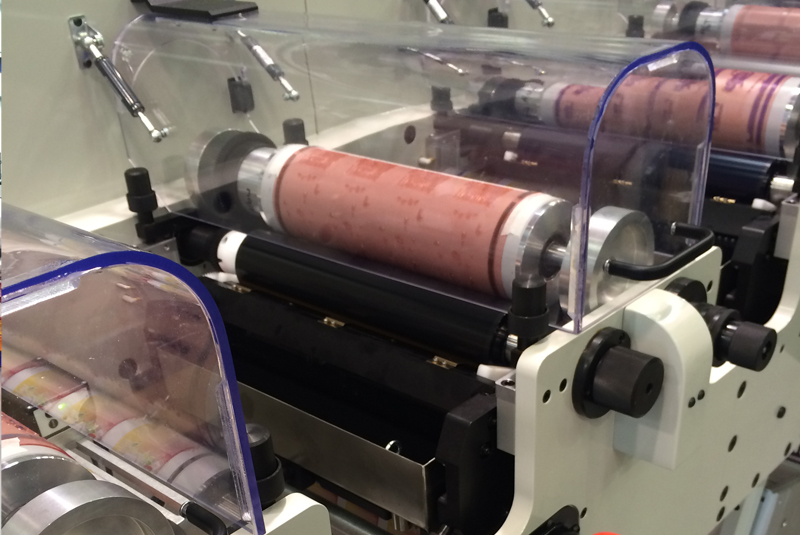

- Modular design supporting 2 to 10 colors, available with either servo or line shaft drive options.

- Offers a wide range of options, including multiple web width selections.

- Equipped with combination drying systems for labels, including IR, UV, and LED UV, along with chill rolls for temperature control.

- Capable of both roll-to-roll and roll-to-sheet conversions.

- Features quick-load tooling for faster setup times and high-quality print output.

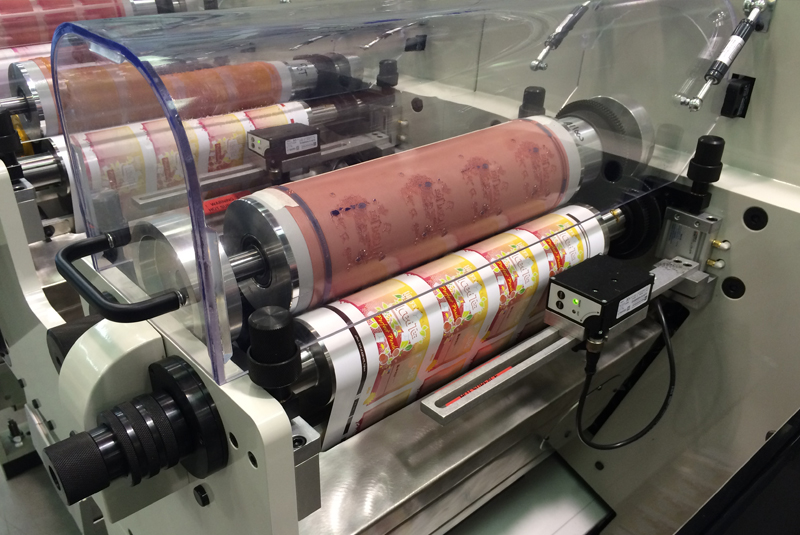

- Ideal for producing labels, security labels, films, packaging, tickets, and cartons.

Applications

The Proflex SE is a multi-purpose workhorse capable of producing a wide variety of products for key Bangladeshi industries:

- Self-Adhesive Labels: High-quality product labels for food, beverage, pharmaceutical, and consumer goods.

- Wrap-Around Labels: For bottles and containers requiring full-body graphics.

- Garment & Apparel Tags: Perfect for the RMG sector, producing hang tags and care labels with precision.

- Flexible Packaging: Sachets, pouches, and wrappers for various products.

- Tickets & Tags: For transit, events, and industrial applications.

- Unsupported Films: Printing on materials like BOPP, PET, and PVC.

Product Comparison Table with Similar Products

| Feature | Focus Proflex SE | Nilpeter FB-Line | Mark Andy Evolution Series | Omet iFlex |

| Drive Technology | Full Servo | Servo options available | Servo (E5/E7) | Servo-assisted |

| Core Advantage | Robust build, modularity, excellent value | High-speed, trusted brand | Ergonomic, user-friendly interface | Innovative pre-registration features |

| Makeready Time | Very Low (Auto-register) | Low | Low (Quick-change features) | Very Low (iLIGHT/iVISION) |

| Target Market | SME to Large Converters (Value & Performance) | Established, high-volume converters | All levels, focus on operator ease-of-use | SME to Large Converters (Innovation) |

| Upgradability | Highly modular | Modular | Modular | Modular |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Proflex SE comes with a service warranty that covers major operational components such as servo drive systems, tension control units, and electronic control panels. Some items—like doctor blades, anilox rollers, UV lamps, and other high-usage parts—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Q1. Is the Proflex SE a good choice for a first-time flexo press buyer in Bangladesh?

A1.Yes. It’s user-friendly, with quick setup and regional support, making it ideal for new ventures with room to grow.

Q2. What is ProFlex used for?

A2. Yes, it handles satin, taffeta, and other materials used for care labels and tags in the RMG sector with precision.

Q3. What is ProFlex material?

A3. ProFlex is a durable, flexible, and lightweight composite, ideal for frequent use and harsh conditions.

Q4. Is financing available for purchasing a Proflex SE?

A4. Yes, financing options are available through local banks with a formal quotation.

Q5. Is local service and support available for this Proflex SE Printing System Machine?

A5. Yes, Prominent Tec in Bangladesh offers installation, training, service, and spare parts.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.