Sliding Heat Press Machine for Heat Transfer Printing

Elevate your production with the PT-J5 Automatic Pneumatic / Hydraulic Heat Press Machine, an advanced industrial press machine for t-shirts engineered for precision and high volume. This automatic heat press machine with slide out drawer functionality is an exceptional t-shirt heat press machine.

| Model name |

PT-J5 |

|---|---|

| Payment Method |

L/C at sight or T/T in advance |

| Min. Order |

01 |

| Warranty |

12 Months. |

| Packaging |

Standard Export Wooden Case |

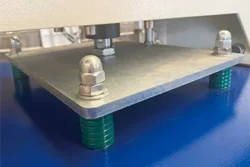

Sliding Heat Press Machine

Ideal for Bangladesh’s dynamic textile and apparel sector, this sliding heat press machine is an essential part of professional finishing solutions, delivering consistent, high-quality results for sublimation transfer, vinyl, and DTF printing on a wide range of fabrics. Designed for businesses that require superior pressure control and higher productivity, the sliding heat press machine enhances workflow efficiency through smooth platen movement and semi-automated operation. Experience reliable performance, reduced operator fatigue, and excellent print quality for all professional shirt printing needs.

Product Specification

| Model | Printing Area | Temperature Range | Voltage/Power | G.W. | Packing Size(mm) |

| PT-J501 | 400*500mm | 0-260℃ | 220V/3KW | 98 | 1050*750*700 |

| PT-J502 | 400*600mm | 0-260℃ | 220V/3.5KW | 104 | 1250*750*700 |

| PT-J503 | 500*700mm | 0-260℃ | 220V/4.5KW | 139 | 1440*800*800 |

| PT-J504 | 400*500mm | 0-260℃ | 380V/3KW | 600 | 1500*800*1700 |

| PT-J505 | 500*700mm | 0-260℃ | 380V/4.5KW | 780 | 1600*900*1700 |

| PT-J506 | 600*800mm | 0-260℃ | 380V/6KW | 600 | 1500*800*1700 |

Advantage & Features

- It can run in both manual and automatic modes. The slide-out design allows for safer and easier layout of materials. Unlike a swing away press, the slide-out drawer saves lateral space.

- The position of the heating plate is managed by an electromagnetic valve, and if there’s a power cut, it can be lifted by hand to protect the fabric.

- Precise temperature control and a user-friendly pressure adjustment knob allow operators to easily account for the thickness of the material, ensuring perfect, quality heat application every time.

- The mechanism is engineered for smooth sliding, making the operation effortless. A double station version of this machine with slide out drawer is also available for even higher throughput.

Applications

The versatility and robust performance of the PT-J5 sliding heat press machine make it indispensable for multiple production environments in Bangladesh:

-

Garment Manufacturing: Ideal for large-scale production, this sliding heat press machine is widely used for T-shirt printing, polos, hoodies, uniforms, and bulk apparel orders. It functions as a dependable shirt heat press in factory settings.

-

Sublimation Printing: The sliding heat press machine is perfectly suited for transferring vibrant, full-color designs onto polyester fabrics and sublimation-coated products, supporting the growing sublimation market in Bangladesh.

-

Fashion & Custom Apparel: Enables brands and designers to produce customized, on-demand garments efficiently using a sliding heat press machine with consistent pressure and heat distribution.

-

Promotional Products: Efficiently transfers graphics onto bags, caps (with optional attachments), mouse pads, ceramic tiles, and other flat promotional items.

-

Workwear & Uniforms: This sliding heat press machine applies durable company logos, branding, and safety markings onto workwear and uniforms.

-

Textile Finishing & Niche Applications: Used for fusing interlinings, embossing fabrics, and creating specialty textile or boutique packaging products.

Product Comparison Table with Similar Products

| Feature/Model | PT-J5 (Industrial Series) | Microtec S4-20 | Gaoshang GS-QD2-7 | Stahls’ Hotronix Fusion IQ |

| Platen Size (Typical) | 40x50cm, 50x70cm, 60x80cm | 40x50cm (4 stations) | 40x60cm, 80x100cm (various sizes) | 40x50cm (16″x20″) |

| Pressure System | Pneumatic Cylinder / Hybrid (Hydro-pneumatic) | Pneumatic | Pneumatic | Pneumatic (Air Fusion) or Magnetic (Auto-Open) |

| Automated Features | Auto open/close, pull-out table, auto pressure, optional rotating stations | Auto open/close, auto slide-out, 4 rotating stations | Auto open/close, drawer sliding worktable | Auto Open/Lock, Auto-adjust pressure, Threadability™ |

| Power (Typical) | 3.0 kW – 6.0 kW | 7.5 kW | 3.8 kW – 8 kW (depending on size) | 1.8 kW (for 16″x20″) |

| Weight (Typical) | 660 kg – 780 kg+ | 710 kg | 375 kg – 700 kg+ | 50 kg (lighter due to different automation mechanism) |

| Voltage | 220V/380V (3-phase typically for larger units) | 220V | 110V/220V/380V | 120V/240V |

Product Warranty

Warranty Period: 12 Months.

Warranty Terms: The Automatic Pneumatic / Hydraulic Heat Transfer Machine comes with a service warranty that covers its core electrical parts, combined pneumatic and hydraulic system, and digital control unit. Some items—like heating plates, silicone pads, and pressure seals—naturally wear out over time and are considered consumables, so they aren’t covered under the warranty. If any covered part stops working during the warranty period, our technicians will handle the repair or replacement, but customers will need to purchase any necessary spare parts. Please note that customers are responsible for all shipping costs when sending or receiving parts or equipment.

Technical & After Sales Service

To help you get the best results, we provide robust after-sales support, including:

- On-site installation, setup, and training to ensure smooth integration into your workflow.

- Field servicing and repair visits upon request for issues that require hands-on attention.

- Dedicated customer service channels, including 24/7 phone support for quick resolution of queries or concerns.

- Regional technical assistance (where available) to reduce machine downtime and maintain productivity.

Delivery Time

30-45 days. Please contact our sales team for precise delivery estimates for machine purchases.

Q1: Difference between pneumatic and hydraulic heat press machines?

A1: Pneumatic heat presses use compressed air for fast, clean pressure. Hydraulic heat press machines use oil for higher, consistent pressure. The PT-J5 sliding heat press machine combines both for strong, even results.

Q2: Is the PT-J5 sliding heat press machine good for garment factories using a sliding heat press machine?

A2: Yes. The PT-J5 is built for high-volume industrial production with automatic operation and durable parts.

Q3: Can the PT-J5 sliding heat press machine press delicate fabrics?

A3: Yes. Its precise temperature control and pressure settings ensure quality heat is applied, protecting delicate and thick fabrics alike.

Prominent Tec Company Information

Address: House No. 99, Lift No. 07, Rd No. 4, Block B, Banani, Dhaka-1213, Bangladesh.

Business Type: Importer, Indenting & Distributor, Agents

Business Range: Printing Machinery & Consumables

Main Products: Textile Label Printing Machine, Garments Printing Machine, Digital Garments Printing Machine, Paper & Packaging Printing Machine, Printing Inks, Chemicals, Mesh, Squeegee, Ribbon, Flexo Photopolymer Plates, CTP Plate

About us: Established in 2010, Prominent Tec is a leading importer, indenting agent, and distributor specializing in advanced printing machinery and high-quality consumables. We represent renowned international brands such as Focus Label Machinery (UK), Ink Tec Inc. (USA), and Azon Printer (Croatia), among others, providing comprehensive printing solutions tailored to the garment, textile, packaging, plastic, and metal printing industries. With a dedicated team of professionals, robust warehouse facilities, and a commitment to exceptional service, Prominent Tec ensures reliable supply and technical support, helping our customers achieve efficiency and excellence in their printing operations.